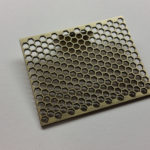

Our QM Series lasers can deliver precise cut parts with thickness up to 5 mm from commercially available sheet metal.

Z-Tech’s QM Series processes Gold, silver, platinum, stainless steel, nickel, molybdenum, titanium, brass, and copper with a repeat accuracy of ±5µm and radius of 16 µm. The laser cutting process eliminates any additional tools necessary in conventional cutting and allows the production of small to medium batches economically feasible. Even single pieces are cost-effective for one of prototypes.