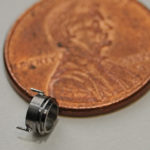

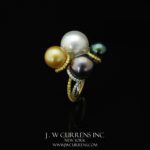

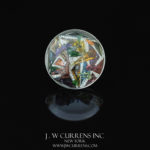

Laser welding process offers the most flexible and versatile metal joining process in today’s manufacturing environment. A Laser (Light Amplification by Stimulated Emission of Radiation) delivers a concentrated heat source at a relatively short time duration resulting in narrow, deep welds at a high rate. The process has been adopted by many industries such as medical device manufacturers, automotive, jewelry, plastic injection mold makers, electronics, and dental laboratories to name a few.

Laser welding has many advantages over conventional welding processes such as TIG, MIG, or electron beam welding (EBW). Laser welding produces minimum heat-affected zones (HAZ). In addition it can generate high rates of heating and cooling so very thin materials can be processed without deformation or warping. Another advantage is that laser welding beam can be transmitted through ambient air rather than requiring a vacuum or inert gas shielding environment resulting in a very clean and high quality weld.

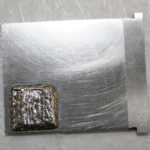

Today’s Laser welding machines are capable of welding both similar and dissimilar metals in addition to most industrial alloys and high reflective metals such as copper, silver, and gold and less reflective metals such as tool steel, stainless steel, titanium, platinum, and palladium.